Earlier this year, I was at Photonics Europe 2022 in Strasbourg. I had a lot of fun with many talks, but there was one topic that really piqued my interest: additive manufacturing. I have always been interested in 3D printing, and I know from experience how useful they can be: printing mechanical pieces in the lab has been a common routine for the past few years, and it makes life so much easier. Besides, the technology has been spreading in almost any branch of science/industry, which has sparkled lots of interesting technologies and hundreds of different applications.

I have been particularly interested in the optical approaches to additive manufacturing. A while ago, I came up with the work from the people in the group of C. Moser regarding tomographic volumetric printing on photo-resins, which is a very nice mix between optics, inversion problems, wavefront shaping and the manufacturing problem.

Last week I also saw the paper that titles this entry. It is a super cool review paper on the different approaches to the problem of additive manufacturing, centered around the photonic systems industry. A young field blooming with so many different ideas is always an exciting thing to see. I think that the authors did a fantastic job in framing the current approaches and caveats, and the list of references covers a lot of interesting papers that I look forward to read. A super cool introduction to the field if you are a newbie.

Additive manufacturing for the development of optical/photonic systems and components

Authors: Gregory Berglund, Anna Wisniowiecki, John Gawedzinski, Brian Applegate, and Tomasz S. Tkaczyk, «Additive manufacturing for the development of optical/photonic systems and components,» on Optica 9, 623-638 (2022)

Abstract:

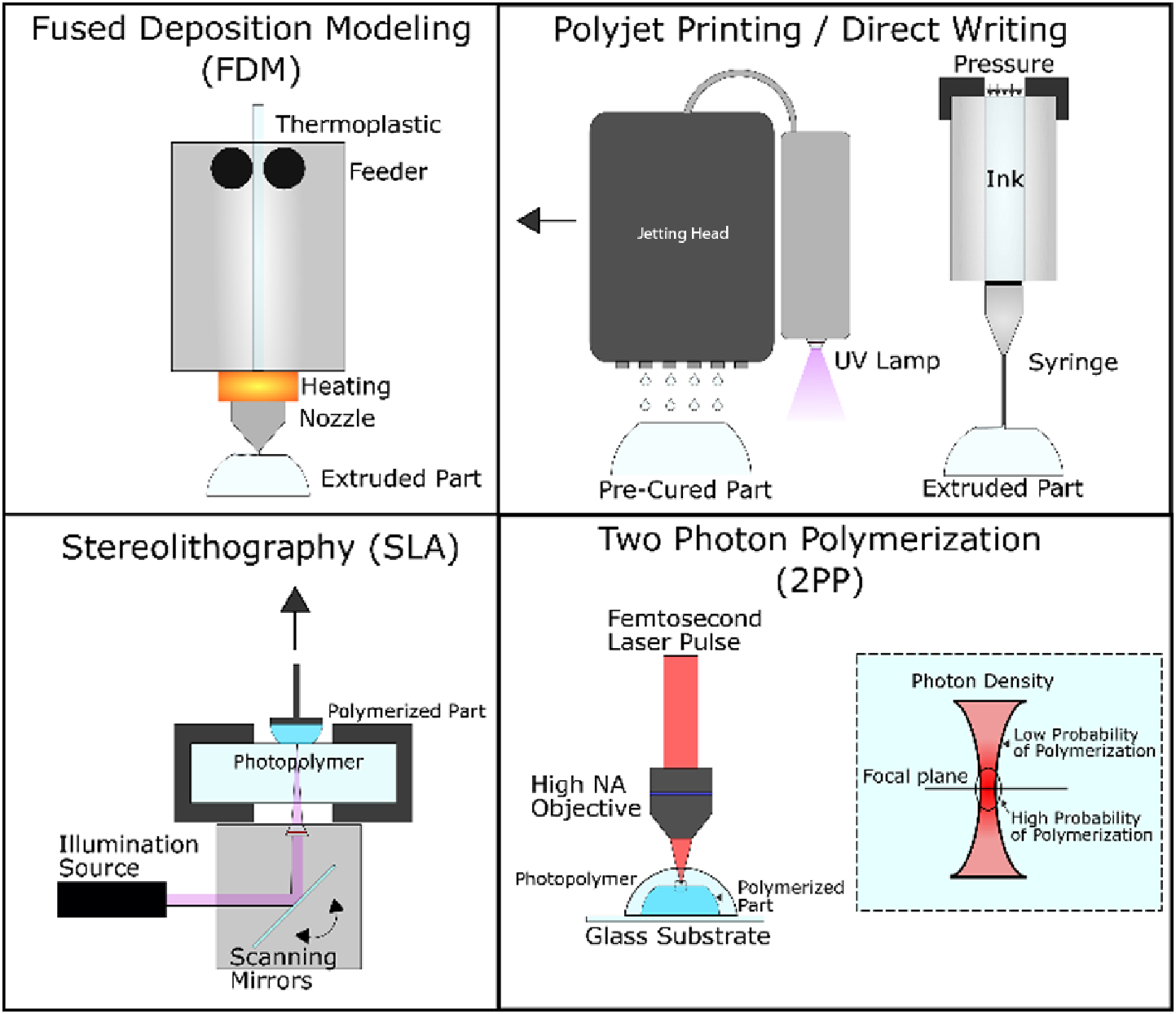

The ambition of this review is to provide an up-to-date synopsis of the state of 3D printing technology for optical and photonic components, to gauge technological advances, and to discuss future opportunities. While a range of approaches have been developed and some have been commercialized, no single approach can yet simultaneously achieve small detail and low roughness at large print volumes and speed using multiple materials. Instead, each approach occupies a niche where the components/structures that can be created fit within a relatively narrow range of geometries with limited material choices. For instance, the common Fused Deposition Modeling (FDM) approach is capable of large print volumes at relatively high speeds but lacks the resolution needed for small detail (>100µm) with low roughness (>9µm). At the other end of the spectrum, two-photon polymerization can achieve roughness (<15nm) and detail (<140nm) comparable to commercial molded and polished optics. However, the practical achievable print volume and speed are orders of magnitude smaller and slower than the FDM approach. Herein, we discuss the current state-of-the-art 3D printing approaches, noting the capability of each approach and prognosticate on future innovations that could close the gaps in performance.

Deja una respuesta